Compounding pharmacy is the art and science of creating customized medicines for each patients specific needs. Compounding is a specialized skill with the potential to help many patients who can benefit from a more personalized medication. Pharmacists who specialize in compounding listen to their patient, discuss the unique situation with the prescribers, then formulate the medication for the patient. The formulation process utilizes:

1:-the knowledge and education of the pharmacist

2:-the highest-quality chemicals available technologically-advanced equipment in a laboratory that is dedicated to compounding

3:-rigorous quality control and quality assurance measures.

Perhaps the most important element in this equation is the compounding pharmacist’s ability and willingness to make personalized patient care the priority. The purpose of a compounded prescription is to maximize a patient’s ability to use the medication and, therefore, gain maximum benefits of that medication. It may be as simple as flavoring a medicine to the patient’s liking. It may involve creating a dosage form that is easier to give to a child or a pet. Perhaps a patient needs a specific dose of medicine or a combination of medicines that isn’t commercially available. Or, a patient may need a customized medication created to treat individual symptoms. These instances and many more are examples of compounding.

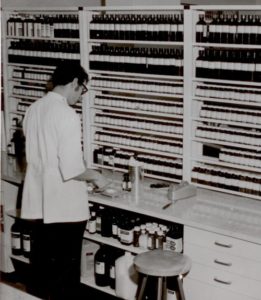

The Modern Equipment of Compounding

Perhaps the most important element in this equation is the compounding pharmacist’s ability and willingness to make personalized patient care the priority. The purpose of a compounded prescription is to maximize a patient’s ability to use the medication and, therefore, gain maximum benefits of that medication. It may be as simple as flavoring a medicine to the patient’s liking. It may involve creating a dosage form that is easier to give to a child or a pet. Perhaps a patient needs a specific dose of medicine or a combination of medicines that isn’t commercially available. Or, a patient may need a customized medication created to treat individual symptoms. These instances and many more are examples of compounding.

Llewellyn’s Pharmacy & Specialty Compounding

The mortar and pestle is still an essential tool in the compounding lab. Used to crush tablets and mix ingredients, the mortar and pestle are often viewed as the icon of pharmacy practice. An alternative to the traditional mortar and pestle is an Electronic Mortar and Pestle, or EMP. The EMP is useful in creating even blends of ingredients in an efficient and safe method. When powders are added into a cream, gel, or lotion, or when such topical applications are mixed together, the compounder can use an ointment slab and spatula, a traditional mortar and pestle (seen above) or even the EMP. Once mixed, placing the preparation in an ointment mill (pictured at left) will decrease the particle size of the powders, making the preparation more pharmaceutically elegant and easier to apply. Compounded dosage forms frequently start in powder-form, and it is of utmost importance that any powders be scrupulously contained to prevent cross-contamination and inadvertent absorption of the drug by anyone in the pharmacy.

Powder containment hoods prevent any loose powder from escaping into the air, trapping it in a HEPA filter for safe, appropriate disposal. These HEPA filters, designed specifically for laboratory use, trap the smallest of particles, much smaller than the naked eye can see. This allows the compounders to safely formulate medicines that will not contain any unwanted ingredients. A capsule machine allows the trained compounder to utilize the familiar form of capsules to make a personalized dosage that is consistent from one dose to the next. This tool allows the compounder to formulate specific combinations and exact doses of medicines without any extra chemicals that may cause allergies or other adverse effects.